Date:2025-08-04 Views:1013

Inhaltsverzeichnis

Laparoskopische chirurgische Schere

Nadelhalter und distaler Gabelkopf

Latch für intravenöse Infusionspumpe

Kieferorthopädisches Bukkalrohr-System

Die Metallpulverspritzguss-Technologie (MIM) ist ein Verfahren, das Metallpulver als Rohstoff verwendet und dabei Kunststoff-Spritzgussprozesse nutzt, um Metallbauteile herzustellen. Ursprünglich wurde sie zur Herstellung keramischer Bauteile aus Oxidpulvern (wie Al₂O₃) eingesetzt – daher die Bezeichnung Keramik-Spritzguss (CIM). Da sowohl MIM als auch CIM Pulver als Ausgangsmaterial verwenden, werden sie gemeinsam als Pulverspritzguss (PIM) bezeichnet.

MIM ist eine neue Formgebungstechnik für Metallbauteile, die Pulvermetallurgie mit moderner Kunststoff-Spritzgusstechnik verbindet. Sie entstand Ende der 1970er-Jahre und wurde zunächst zur Herstellung leichter Waffenkomponenten genutzt. In den 1980er-Jahren erlangte das Verfahren die Aufmerksamkeit der US-amerikanischen Medizintechnik-Industrie. Folglich halten Medizin- und Dentalmarkt einen bedeutenden Anteil am US-MIM-Bauteile-Markt. Zwischen 1998 und 2008 gewannen in den jährlichen MPIF-Design-Wettbewerben (Metal Powder Industries Federation) 14 medizinische und dentale Pulvermetallurgie-Teile Auszeichnungen – 12 davon waren MIM-Bauteile. Dies zeigt, dass MIM-Bauteile in den US-amerikanischen Medizin- und Dentalbranchen breite Akzeptanz gefunden haben und die Fertigungstechnologie ein hochentwickeltes Niveau erreicht hat. Nachfolgend werden die 14 preisgekrönten Produkte der MPIF-Pulvermetallurgie-Design-Wettbewerbe von 1998 bis 2008 vorgestellt.

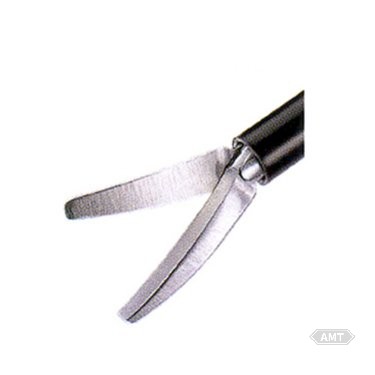

Diese laparoskopische chirurgische Schere wird mittels MIM aus 17-4PH-Edelstahlpulver gefertigt und verfügt über Koagulationsfunktion. Sie besteht aus einem Spiralgetriebe und zwei einzelnen Scherenblättern mit einer Dichte von 7,5 g/cm³. Das 20-Zahn-Spiralgetriebe wird in einem speziellen „Schwimmenden-Kavitäten“-Werkzeug hergestellt. Die Blätter werden präzisionsbearbeitet und wärmebehandelt, um die gewünschte Krümmung und Schneidekante zu erzielen. Im Vergleich zur Bearbeitung von Spiralgetrieben reduziert MIM die Kosten um 80 %.

Abb. 10-17 Laparoskopische chirurgische Schere

Die endoskopische Schere wird für minimal-invasive Herz-, Allgemein- und Rekonstruktionschirurgie über MIM aus 17-4PH-Edelstahlpulver gefertigt. Sie besitzt eine Dichte von mindestens 7,5 g/cm³, eine Streckgrenze von ≥ 966 MPa und eine Zugfestigkeit von ≥ 1069 MPa. Die Bauteile sind nach Formgebung und Sintern gerade; der Kunde biegt sie in die erforderliche Krümmung. Im Vergleich zu bearbeiteten Bauteilen aus 303-Edelstahl erzielt MIM erhebliche Kosteneinsparungen.

Abb. 10-18 Endoskopische Schere

Diese Bauteile werden über MIM aus 17-4PH-Edelstahlpulver gefertigt und haben eine Dichte von 7,68–7,72 g/cm³. Der distale Gabelkopf weist eine Härte von 35–38 HRC, eine Dehnung von 10 % und eine Streckgrenze von 1100 MPa auf. Der Nadelhalter hat eine Härte von 38–42 HRC, eine Dehnung von 8 % und eine Streckgrenze von 1070 MPa. Sie kommen im daVinci-Robotik-Chirurgie-System für minimal-invasive Eingriffe zum Einsatz und bieten höchste Präzision und Beweglichkeit.

Abb. 10-19 Nadelhalter und distaler Gabelkopf

Diese laparoskopischen Backen werden über MIM aus 17-4PH-Edelstahlpulver gefertigt und bestehen aus Ober- und Unterbacken, einem Halter und einem I-Träger. Sie werden für Hochkompressionsanwendungen in laparoskopischen Eingriffen verwendet. Die gesinterten Bauteile haben eine Dichte von 7,6 g/cm³ und besitzen dünne Wände sowie komplexe Geometrien. Das Design ermöglicht hohe Kompression – entscheidend für schnelles Schmelzen von Behältern ohne thermische Beeinflussung.

Abb. 10-20 Laparoskopische Backen

Dieses komplex geformte Bauteil wird über MIM aus 17-4PH-Edelstahlpulver für medizinische Nähgeräte hergestellt. Es ermöglicht einhändige Bedienung zur sicheren und gleichmäßigen Naht. Das Teil hat eine Dichte von 7,7 g/cm³, eine Zugfestigkeit von 897 MPa und eine Streckgrenze von 731 MPa. Zusätzliche Arbeitsgänge: Bohren von drei Löchern, Umformen und Finishen.

Abb. 10-21 Nähklaue

Dieses komplex geformte Bauteil wird mittels Pulvermetallurgie aus 316-Edelstahlpulver für medizinische Infusionspumpengriffe für intravenöse Lösungen gefertigt. Es besitzt eine Dichte von 6,7 g/cm³, eine Zugfestigkeit von 448 MPa, eine Streckgrenze von 290 MPa und eine Dehnung von 11,5 %. Der Latch muss hohen Belastungen und wiederholten Betätigungen standhalten, ohne Verschleiß oder Bruch. Die Umstellung auf Pulvermetallurgie spart jährlich 100.000 $.

Abb. 10-22 Latch für intravenöse Infusionspumpe

Das Biopsie-Instrument umfasst elf über MIM aus 316L-Duplex-Edelstahl gefertigte Bauteile. Sie haben eine Dichte von ≥ 7,52 g/cm³, eine Zugfestigkeit von 503 MPa, eine Streckgrenze von 296 MPa, eine Dehnung von 40 % und eine Härte von 70–80 HRB. Das Instrument ist für einhändige Bedienung unter Ultraschallkontrolle konzipiert und bietet gegenüber bearbeiteten Bauteilen Kosteneinsparungen von über 50 %.

Abb. 10-23 Biopsie-Instrument

Das Kegelrad wird mittels Pulvermetallurgie aus 304-Edelstahlpulver für den Antriebsmechanismus eines chirurgischen Faserschneiders gefertigt. Es hat eine typische Dichte von 6,6 g/cm³, eine Streckgrenze von 207 MPa und eine Härte von 63 HRB. Früher aus zwei bearbeiteten Bauteilen verschweißt, reduziert das PM-Rad die Kosten um 70 %.

Abb. 10-24 Kegelrad

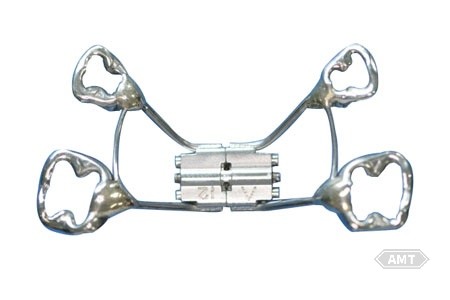

Diese Serie umfasst 32 MIM-Brackets und 2 MIM-Slides aus 17-4 PH-Edelstahl, wärmebehandelt auf eine Zugfestigkeit von 1276 MPa, eine Streckgrenze von 1103 MPa, eine Dehnung von 7 % und eine Härte von 38–42 HRC. Es ist das erste vollmetallische Damon-Selbstligierungsgerät, das ein solches Bukkalrohr-System verwendet, mit einer Jahresproduktion von über 12 Millionen Teilen.

Abb. 10-25 Kieferorthopädisches Bukkalrohr-System

Dieses komplexe Bauteil wird über MIM aus 17-4PH-Edelstahlpulver für ein manuelles faseroptisches Dentalgerät gefertigt. Es hat eine Dichte von 6,7 g/cm³ und weist 19 kritische Maße mit Toleranzen von ±0,076 mm oder kleiner auf. Fünf dieser Maße haben Toleranzen von ±0,0254 mm. Das Teil wird im Grünzustand gebohrt, da der Bohrer sehr dünn ist, und besitzt sieben Bezugsflächen. Durch MIM entfielen Bearbeitungsabfälle und die Ausbeute stieg von 60 % auf nahezu 100 %.

Abb. 10-26 Dentalmanifold

Diese drei Bauteile werden über MIM aus 17-4PH-Edelstahlpulver für das Damon-3-MX-Selbstligierungs-Kieferorthopädiegerät hergestellt. Sie haben eine Dichte von 7,5 g/cm³, eine Zugfestigkeit von 1186 MPa und eine Streckgrenze von 1090 MPa. Die Teile werden wärmebehandelt, dann vom Kunden getrommelt und vor der Montage hartgelötet.

Abb. 10-27 Kieferorthopädisches System: Bracket, Slide und Haken

Dieses Gerät wird über MIM aus nickelfreiem Edelstahl gefertigt und besteht aus zwei Teilen: einem mit kugelgestängeltem Stab und Pfanne sowie einem zweiten mit Haken. Nach dem Sintern und Polieren wird die Kugel in die Pfanne eingepresst. Die Teile haben eine Dichte von 7,6 g/cm³, eine Zugfestigkeit von 659 MPa, eine Streckgrenze von 552 MPa und eine Dehnung von 22 %. Das Design reduziert die Herstellkosten gegenüber Präzisionsguss deutlich.

Abb. 10-28 Funktionsapparat

Diese komplexe, eng tolerierte Haken-Getriebe-Baugruppe wird in einem Stück per MIM hergestellt und erfordert keine Sekundärbearbeitung. Sie hat eine Dichte von über 7,65 g/cm³, eine Zugfestigkeit von 900 MPa, eine Streckgrenze von 730 MPa und eine Härte von 25 HRC. MIM senkt die Produktionskosten gegenüber der Bearbeitung aus Vollmaterial um etwa 70 %.

Abb. 10-29 Artikulationsrad

Der Pin-Shroud wird über MIM aus 316L-Edelstahlpulver für das Schulter-Reparatur-Implantat hergestellt. Er verankert genähte Sehnen im Knochen bei arthroskopischer Labrum-Reparatur. Das Teil hat eine Dichte von 7,85 g/cm³, eine Zugfestigkeit von 538 MPa, eine Streckgrenze von 200 MPa und eine Oberflächenhärte von 69,4 HRB. Die MIM-Netform-Fertigung ersetzt drei zuvor per Draht-ERMS bearbeitete und lasergeschweißte Bauteile und verkürzt die Endmontage von 15 auf 5 Minuten pro Einheit.

Abb. 10-30 Pin-Shroud

Leave your email for more ebooks and prices📫 !

Kontakt:Fidel

Tel:021-5512-8901

Mobil:19916725892

E-Mail:sales1@atmsh.com

Adresse:Nr. 398 Guiyang-Straße, Yangpu, China